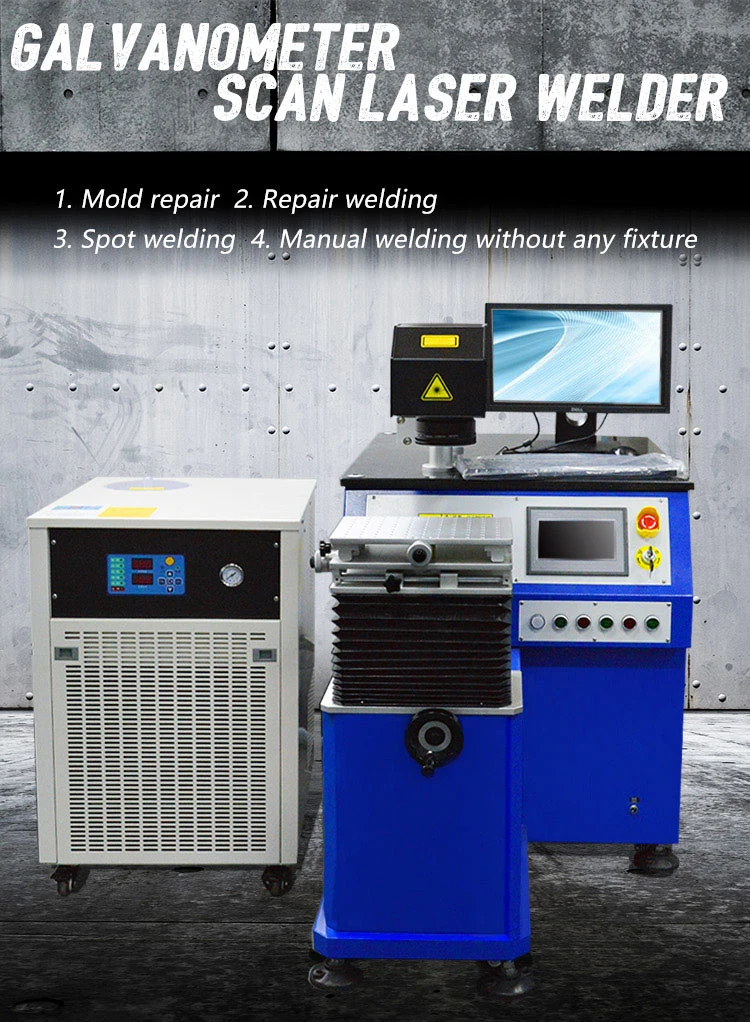

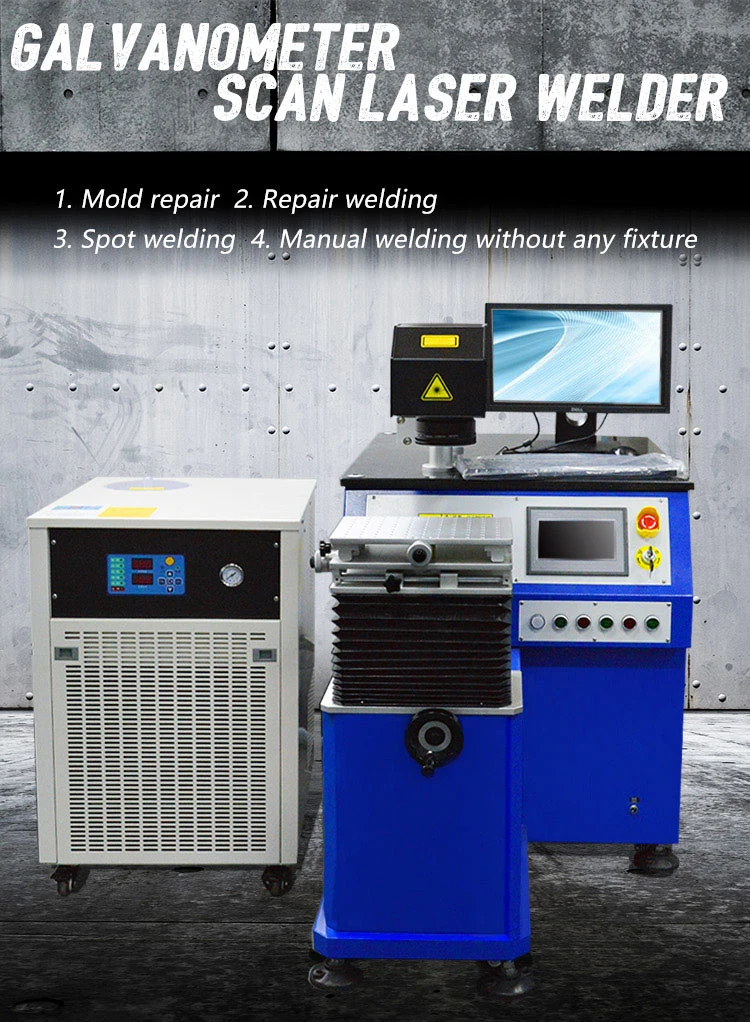

- Overview

- Product Description

- Detailed Photos

- Samples

- Other Products

- Company Profile

- FAQ

Basic Info.

Model NO.

MT-W400YG

Type

Automatic Laser Welding Machine

Protective Gas

Single 1(Argon)

Repetition Precision

0.01mm

Laser Axial Rotation

Fixed/360°

Gross Weight

150kg

Voltage

220V±10%/50Hz/30A/380V±10%/50Hz/40A

Pulse Frequency

<50Hz

Positioning

Microscope

Controller System

PLC or PC(CNC2000)

Working Table Load

<200kg

Max.Pulse Energy

90j-150j

Max.Welding Thickness

0.1-2.0mm

Transport Package

Standard Export Wooden Box

Trademark

MACTRON

Origin

Guangdong, China

Production Capacity

200sets/Month

Product Description

Product Description

Galvo laser welding machine adopts high-speed scanning head to weld, the speed is up to 7000mm/s, which greatly improves production efficiency. The digital scanner interface has a strong anti-jamming ability and better stability. It is equipped with dedicated control software that is compatible with multiple format documents and a high-power cooling system, which can meet the work requirements of mass production, It is a very cost-effective welding device.

Specification:

A: We will help you choose the suitable machine and share you the solution; you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine, for product welding or repair or other application

Q: When I got this machine, but I don't know how to use it. What should I do?

A: Our engineer will do training online. If needed, we will arrange our engineer to your factory for training or you can send the operator training in our factory.

Q: What's a package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Q: What's the delivery time?

A: As per your requirement, we will suggest a suitable machine. The exact delivery time as per your machine.

Q: Can you arrange the shipment for me?

A: We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.

Specification:

| Model | MT-W200YG | MT-W300YG | MT-W400YG |

| Laser Power | 200W | 300W | 400W |

| Laser Type | YAG Laser Source | ||

| Wavelength | 1064nm | ||

| Max. Pulse Energy | 90 J - 150 J | ||

| Max. Welding Thickness | 0.1-2.0mm | ||

| Gross Power | ≤13KW | ||

| Voltage | 220V±10% / 50Hz /30A | 380V±10% / 50Hz / 40A | |

| Pulse Width | 0.3-20ms | ||

| Frequency | 1-100Hz | ||

| Spot Adjustable Range | 0.2-2mm | ||

| Positioning | Red Indicator | ||

| Repeatability | ±0.01mm | ||

| Control System | PLC or PC(CNC2000 ) | ||

| Working Table (XYZ) | 200mm×200mm×200mm - 500x500x200mm ( Optional) | ||

Features:

1, The use of high-speed scanning galvanometer for laser positioning, the speed of up to 7000mm / s, greatly reducing the welding time between the empty time, which greatly improve production efficiency;

2, Digital galvanometer interface, anti-interference ability, better stability;

3, All Chinese special control components, powerful, easy to operate, compatible with a variety of format files;

4, High-power cooling system to meet the continuous production of mass production.

5, Processing speed, thermal deformation is minimal, does not affect the product within the electronic components or chemical composition of the performance;

6, Can be equipped with different welding range of field mirror and welding power;

7, With the corresponding supporting institutions to achieve online production.

1, The use of high-speed scanning galvanometer for laser positioning, the speed of up to 7000mm / s, greatly reducing the welding time between the empty time, which greatly improve production efficiency;

2, Digital galvanometer interface, anti-interference ability, better stability;

3, All Chinese special control components, powerful, easy to operate, compatible with a variety of format files;

4, High-power cooling system to meet the continuous production of mass production.

5, Processing speed, thermal deformation is minimal, does not affect the product within the electronic components or chemical composition of the performance;

6, Can be equipped with different welding range of field mirror and welding power;

7, With the corresponding supporting institutions to achieve online production.

Application

It is used in off-line / on-line welding of high-volume production enterprises in electronics, communication, hardware and other industries, including welding of fine parts such as fine microelectronic components, integrated circuit leads, high power diodes, type batteries, mobile phone shields, Shell, metal capacitor shell, computer hard drive, micro-motor, sensor, metal shielded net, razor blade and other types of electronic products, high efficiency laser spot welding or sealing welding.

https://mactrontech.en.made-in-china.com/product-list-1.html

About Us

Dongguan Mactron Technology Co., Ltd (Mactron Technology Co., Limited) mainly manufactures and sells products like Fiber Laser Marking Machine , UV Laser Marking Machine , Co2 Laser Marking Machine, Laser Printer, Co2 laser cutting and Engraving Machine, Fiber Laser Cutting Machine, Laser Flat Bed, Customized Laser Equipment and a full laser spare parts. The laser equipment system is widely used in many fields, including textiles, leather, clothing, industrial fabrics, advertising, technology products, printing, packaging, electronics, pharmaceuticals, furniture, hardware tools, molds, and other industries.

FAQ

Q: I know nothing about this machine, what type of machine should I choose?A: We will help you choose the suitable machine and share you the solution; you can share us the following information

1. what material will you weld

2. The welding material thickness

3. Is it joint welding or over-lay welding

4. What is the exact usage for the machine, for product welding or repair or other application

Q: When I got this machine, but I don't know how to use it. What should I do?

A: Our engineer will do training online. If needed, we will arrange our engineer to your factory for training or you can send the operator training in our factory.

Q: What's a package, will it protect the products?

A: We have 3 layers package. For the outside, we adopt wooden cases free of fumigation. In the middle, the machine is covered by foam, to protect the machine from shaking. For the inside layer, the machine is covered by waterproof plastic film.

Q: What's the delivery time?

A: As per your requirement, we will suggest a suitable machine. The exact delivery time as per your machine.

Q: Can you arrange the shipment for me?

A: We can arrange the shipment for our clients by sea or by air. Trading terms FOB, CIF, EXW are available.