Basic Info.

Product Description

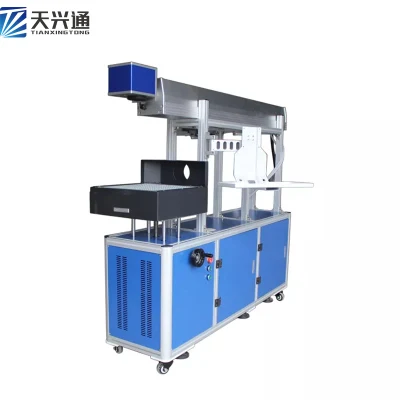

Machine picture:

CO2 laser Features:

1) High precision marking, swift, engraving depth controllable.2) Applied on most of non-metal material.

3) Excellent beam quality, high photoelectric conversion efficiency, good performance and can be competent at fine processing.

4) Windows interface adopted, compatible with CORELDRAW, AUTOCAD, PHOTOSHOP, etc.

5) Support PLT,PCX, DXF,BMP and other formats, execute SHX, TTF font directly, support automatic code, serial number, batch number, two-dimensional bar code marking, and garphic anti marking function available.

NO | Model | RF-F-CO2 |

1 | Working size | 100X100/ 200X200/ 300X300mm |

2 | Laser Power | 60W/80W/90W/100W/150W Reci or US Synrad metal laser tube |

3 | Galvo system | High quality Galvo scanning system |

4 | Laser Power Control | 0-100% Software Controlling |

5 | Axial Speed | 0-7000mm/s |

6 | Motion System | Servo Motor/ stepper motor |

7 | Repeat Location Accuracy | ± 0.01mm |

8 | Voltage | 110V/220V, 50HZ/60HZ |

9 | Cooling System | Industrial water chiller |

10 | Min character | 0.3mm |

11 | User Control | Digital Screen Panel |

12 | Operate system | Windows XP/7/8/10 |

13 | Format Support | PLT/DXF/AI/SDT/BMP/JPG/JPEG/GIF/TGA/PNG/TIF/TIFF CorelDraw/PhotoShop/AutoCAD/Illustrator |

14 | Software | Original EZCAD |

15 | Package size | Length*width*height :1860x760x1320mm Gross weight:230kgs |

Marking & Engraving material:

Wood, paper, leather,cloth, plexiglass, epoxy, acrylic, unsaturated polyester resin and other non-metal materials.

Detailed image:

Reci co2 glass laser tube, water cooling mode, long lifetime.

High quality marking head, with high speed galvanometer and field lens.

Stable metal work platform, and high quality push button switches and power supplies

Water cooling system, water chiller CW3000, or CW5000, CW5200 as option.

Training Service

As well, you may send your technician to our company to learn how to operate machines.

Quality Guarantee

We arrange final test before shipment. We run the machine without material for a few days, and then cut materials for test. After making sure machine is the best performance, then ship out the machine.

Operating guide

Explain the use of machines and software. Guide the customer proper use, extend product life and reduce energy consumption.

Machine maintenance&Warranty

Explain the maintenance of machine parts to extend product life and save the energy consumption

The whole set of machine warranty period is 1 year.

Contact us: